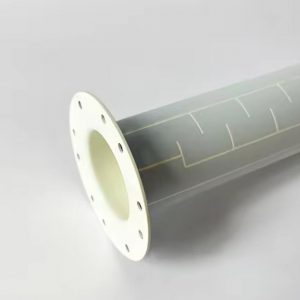

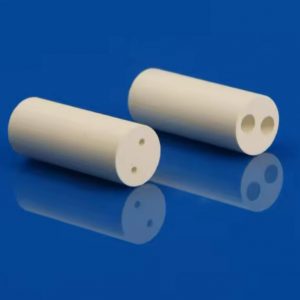

High Thermal Conductivity Hexagonal Boron Nitride Ceramic Cylinder

- وصف

- سؤال

High Thermal Conductivity Hexagonal Boron Nitride Ceramic Cylinder

Hexagonal Boron Nitride rod has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called نيتريد البورون السداسي (HBN) or white graphite.

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & درجة حرارة عالية. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won’t break even repeat this test with 100 مرات.

خصائص المواد: * الموصلية الحرارية العالية * مقاومة ممتازة للصدمات الحرارية * تمدد حراري منخفض * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability | ||||

Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB | ||||

Ability | ||||

Max size:500x500x200mm Best tolerance: +/-0.05مم سماكة: 0.5 to 200mm High purity and composited Boron Nitride are both available |

خصائص المواد:

غرض | وحدة | BN-2000 | BN-2300 | BN-2800 | BN-3000 |

Main Content | - | BN>99% | BN+Al2O3 | BN + AlN | BN+ZrO2 |

اللون | - | أبيض | Light Grey | Dark Grey | Dark Grey |

كثافة | ز / سم3 | 1.95-2.00 | 2.25-2.35 | 2.75-2.85 | 2.90-3.00 |

قوة العاطفة | الآلام والكروب الذهنية | 30 | 65 | 85 | 90 |

قوة الضغط | الآلام والكروب الذهنية | 55 | 145 | 205 | 220 |

Electrical Resistivity | Ω·سم | >1014 | >1013 | >1013 | >1012 |

الأعلى. Use Temp. (Air) | درجة مئوية | 900 | 1,000 | 1,000 | 1,000 |

الأعلى. Use Temp. (Vacuum) | درجة مئوية | 1,900 | 1,750 | 1,800 | 1,750 |

الأعلى. Use Temp. (خامل) | درجة مئوية | 2,000 | 1,750 | 1,800 | 1,750 |

توصيل حراري | W / مك | 35 | 30 | 85 | 30 |

كوت (25 - 1,000 درجة مئوية) | 10-6/ك | 1.5 | 2 | 2.8 | 3.5 |

High Thermal Conductivity Hexagonal Boron Nitride Ceramic Cylinder

التطبيقات

2. Vacuum melting crucibles

3. CVD crucibles

4. Microcircuit packaging

5. Sputtering targets

6. High precision sealing, brazing, and metallizing fixtures

7. Microwave tubes

8. Horizontal caster break rings

9. Low friction seals

10. Plasma arc insulators

11. High temperature furnace fixtures and supports