12V PTC Ceramic Heating Element

12V PTC Ceramic Heating Element

- Description

- Inquiry

12V PTC Ceramic Heating Element

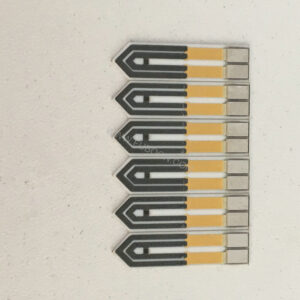

We produce every kind of super quality 12V PTC CERAMIC HEATING ELEMENTS for Auto O2 sensor heaters with the advantages of long service time, fast heating rate, energy-efficient and eco-friendly.

1 | Part No. | FU023 |

2 | Usage | 12V PTC Ceramic heater element for O2 Sensor |

3 | Working Voltage | 12 VDC |

4 | Heating Resistance | 5.8Ω±0.4Ω(23°C±2°C) |

5 | Dimension of product | length:56mm, diameter3.0mm |

6 | Electrode | Nickel leadson the surface of electrode |

7 | Advantages | (1)Long lifetime: airproof structure ; the condition of deformation .can’t exit (2)Temperature rise quickly (3)Excellent insulation (4)Energy efficient and thermal conductivity super—heating simultaneously both from inside and outside (5)Small and compact (6)Equalized heat distribution and high power density. (7)High cost performance. |

Ceramic heater technology benefits:

* A fraction of the energy consumption compared to conventional element heater

* Long-lasting (non-aging)

* Time to ignition 60~90 seconds

* Tested to 100,000 cycles

* Easy to install and retrofit

*100°C at steady-state temperature

* Impervious to oxidation and corrosion

Alumina Ceramic Heater Design Structure

one pieces.

■ Rectangular alumina ceramic heating element

■ Round shape alumina ceramic heating element

■ Rod shape alumina ceramic heating element

Thermal Properties for Alumina Heater | ||

Item | Unit | Value |

Vickers Hardness | Gpa | 11.5 |

Flexural Strength | Mpa | 300 |

Compressive Strength | Mpa | 2000 |

Modulus of Elasticity | Gpa | 300 |

Poisson’s Ratio | — | 0.22-0.23 |

Fracture Toughness | Mpam1/2 | 3.5-4.0 |

Thermal Conductivity | W/(m·k) | 25 |

Thermal Expansion Coefficient | 10-6/℃ | 6.5-7.5 |

Thermal Shock Resistance | △T℃ | 200 |

Maximum Use Temperature | ℃ | 1600 |

Dielectric Strength | KV/mm | >12 |

Dielectric Constant | εr | 9-10 |

Dielectric Loss Angle (1MHz) | — | 0.0002 |

Volume Resistivity | Ω.m | >1015 |

Specific Heat | J/(kg·k) | 0.78×103 |