Pellet Stoves Used 230V Ceramic Heater Element

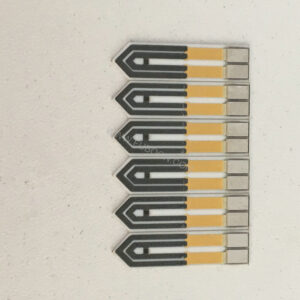

230V Ceramic Heater Elementfor Pellet Stoves

- Description

- Inquiry

Pellet Stoves Used 230V Ceramic Heater Elementfor Pellet Stoves

Characteristic

1.High temperature-resistance c High Quality 230V Ceramic Heaters for Pellet Stoves which can reach a permanent working temperature above 950°C+/-

2.Energy saving, super fast heating-up

3.Air can through and around inside and outside of the heater.

Heat can be transfered from both inside and ouside of the heating element.

4.Electrically oxidation and corrosion-resistant

5.High load-bearing capacity(thermal shock resistance, cycles)

6.Customization the igniters according to customers’ specific requirement.

230V Ceramic Heater Element for Pellet Stoves

Application

One special application area for FUBOON’s high temperature ceramic piezo igniter is in heating systems that use solid fuels such as wood pellets as energy source. The challenge here is to

ignite the biomass in a very short time while retaining very low emission values. This can be perfectly achieved by FUBOON’s hot surface ceramic igniter.

Ceramic hot surface igniter for pellet burners need only approx. 1/10 of the energy of that needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 200 Watt. Depending

on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is ex-tremely short. This also means minimal emissions!

Igniting wood chips, firewood, coal bricks or other biomass (such as corn, etc.) is possible.

Mass customization is available.

Pellet Stoves Used 230V Ceramic Heater Element

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |