Alumina Metallized Ceramics for Electronic Applications

- Description

- Inquiry

Customized Alumina Metallized Ceramics for Electronic Applications

The prime features of alumina metalized ceramics

1. High bonding/brazing strength with ideal vacuum tightness between the assembly

2. With diamond-like hardness to be 85 HRV and superb compressive strength

3. Great insulation strength and volume resistivity that fit for various high voltage high current applications

4. Chemical stability, anti-aging even if it works in a variety of harsh environments, free of rust forever.

5. Over 276 times wear resistance in comparison with stainless steel, it leads to a long service lifespan.

Customized Alumina Metallized Ceramics for Electronic Applications

The key parameters capability of metalized ceramics

| Leak rate | ≤1×10-11 Pa•m3 / s | Metal layer tensile strength | ≥ 150Mpa |

| Volume Resistivity | ≥108Ω•cm | CTE | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation strength | ≥18kV/mm (D•C) | Dielectric constant | 9~10(1MHz, 20°C) |

| Cosmetic quality: 1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

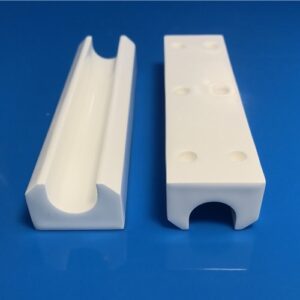

The description of the metalized ceramics

We manufacture a diversity of metalized ceramics with different specifications, like metallized ceramic tubes, metallized ceramic rings, metallized ceramic substrates, and so on. These Metallized Ceramics are made of aluminum oxide, zirconium oxide, or beryllia ceramics via dry pressing, injection molding, or hot pressing.

We can proceed with small part-size to large part-size, the min. diameter can be 1mm, the largest diameter is up to 800mm. In order to meet customers’ different needs, we offer a selection of types of metallization, the typical ones as below:

1. Ceramic base + Molybdenum (Mo/Mn) metallization

2. Ceramic base + Mo/Mn metallization + Nickle(Ni) plating

3. Ceramic base + Silver(Ag) plating

4. Ceramic base + Tungsten (W) metallization + Gold(Au) plating

We offer different grade precision metallized ceramics when you need these ceramic components to be very precise, these vacuum ceramic components would be further proceeded via lapping, grinding, CNC machining before metallization on-site production. The finest tolerance can be +/-0.001 for length, +/-0.005 for both inner and outer diameter.

The typical application of metalized ceramics

Metalized ceramics are widely used in electronics, high-vacuum technology, sensors, and medical fields,

like vacuum interrupters, electron tubes, feed-throughs, medical linear accelerators/ power tubes, photomultipliers, X-ray tubes, and pressure sensors

Related Products

Al2o3 ceramic shaft piston plunger

Al2o3 ceramic shaft piston plunger

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

Alumina liner tube sleeve cylinder for pump

Alumina liner tube/sleeve/cylinder for pump

Electrical ceramic insulators

ceramic insulators for heaters electrical ceramic insulators

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

Furnace Kiln High Temperature Resistant Alumina Ceramic Tube

High-temperature alumina ceramic tube

Alumina Ceramic precision ball

Alumina Ceramic precision ball for bearing

Alumina Ceramic Bushing Sleeve Tubes

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

99% Al2O3 mechanical Alumina oxide ceramic seal ring

99% Al2O3 mechanical Alumina oxide ceramic seal ring