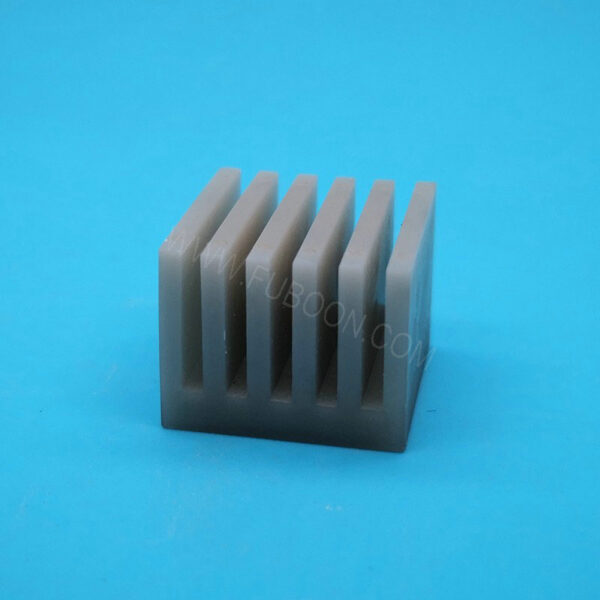

Aluminum Nitride Ceramic Heat Sinks

- Description

- Inquiry

Aluminum Nitride Ceramic Heat Sinks

Aluminum Nitride (AlN) is an excellent material to use if high thermal conductivity and electrical insulation properties are required; making it an ideal material for use in thermal management and electrical applications. Additionally, AlN is a common alternative to Beryllium Oxide (BeO) in the semiconductor industry as it is not a health hazard when machined.

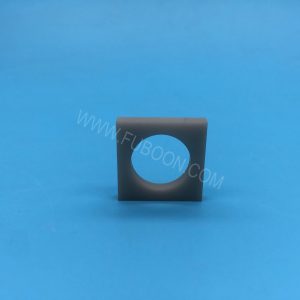

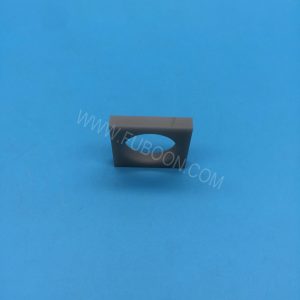

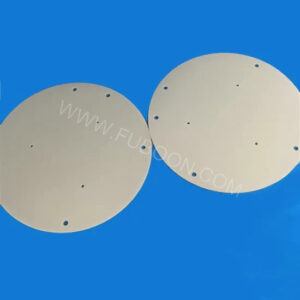

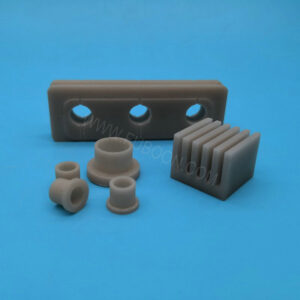

Ceramic Heat Sink Made of Aluminum Nitride Ceramic, offers supreme thermal conductivity, electrical insulation, and lightweight, combining efficiency and sustainability in one. Applications in electronic components, telecom network communication, high power LED light or display, PCB and industrial.

Advantage of Aluminum Nitride Ceramic Heat-Sink

- Anti oxidation at <900°C

- Corrosion resistant

- Waterproof

- Electrical isolation

- 30% lighter than Aluminium

- Eco-friendly

Aluminum Nitride Ceramic Heat-Sinks

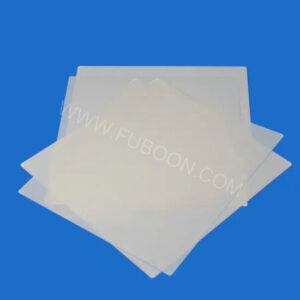

With its properties of electrical insulation and excellent thermal conductivity, Aluminum Nitride Ceramics is ideal for applications where heat dissipation is required. In addition, since it offers a coefficient of thermal expansion (CTE) near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components. Advantages: · High thermal conductivity combined with good electrical insulation characteristics. · Exceptional stability when exposed to many molten salts. · Thermal stability up to at least 1500°C · Favorable mechanical characteristics extending into the high temperature range. · Low thermal expansion and resistance to thermal shock. · Special optical and acoustic characteristics. | ||||

Physical Properties | ||||

· Flexural strength is 300 ± 5MPa · Coefficient of thermal expansion is 5.6×10-6K-1 (20-1000°C) · Thermal conductivity is 70-180 W/m.K · Insulation resistance is >1012Ωcm (20°C) · Low Pressure Injection Molding · Cold Isostatic Press · Dry Press · Tape Casting · Precision Machining Processing | ||||

Products: · AlN Ceramic Heat-sinks for high power system · AlN Crucible for Metal Melting · AlN Ceramic Rod · AlN Ceramic Heater · Ceramic Substrate · Custom Shape |

Aluminum Nitride Ceramic Heat Sinks

Property | Unit | Alumina Nitride Ceramic |

Color | Grey | |

Mechanical Properties | ||

Density | g/cm3 | 3.31 |

Compressive Strength | MPa | 2100 |

Flexural Strength | MPa | 335 |

Vickers Hardness | GPa | 11 |

Thermal Properties | ||

Maximum Temperature | ||

Oxidizing | °C | 700 |

Inert | °C | 1300 |

Thermal Conductivity | 30 | |

@ 25°C | W/mK | 180 |

@ 300°C | W/mK | 130 |

Coefficient of Expansion | ||

CTE 25°C ➞ 100°C | 10^-6/°C | 3.6 |

CTE 25°C ➞ 300°C | 10^-6/°C | 4.6 |

CTE 25°C ➞ 500°C | 10^-6/°C | 5.2 |

CTE 25°C ➞ 1000°C | 10^-6/°C | 5.6 |

Specific Heat | 100°C | 750 |

Thermal Shock Resistance ΔT | °C | 400 |

Electrical Properties | ||

Dielectric Constant | 1 MHz | 8.6 |

Dielectric Strength | kV/mm | >15 |

Loss Tangent | 1 MHz | 5×10^-4 |

Aluminum Nitride Ceramic Heat Sinks

Aluminum Nitride Ceramics is one of the few materials that offers electrical insulation and high thermal conductivity. This makes AlN extremely useful in high power electronic applications in heat sink and heat spreader applications.