Aluminum Nitride Ceramic Heater

- Description

- Inquiry

Aluminum Nitride Ceramic Heater

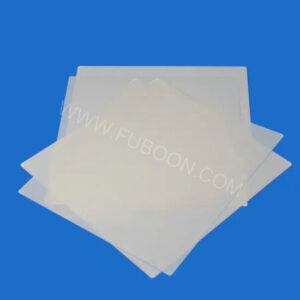

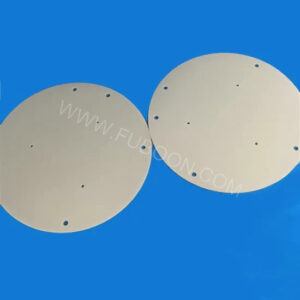

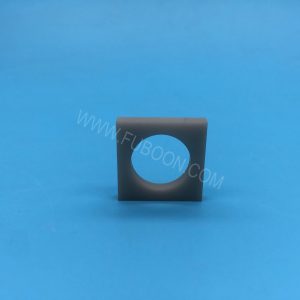

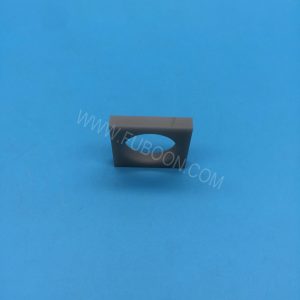

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests.

Aluminum Nitrides (AlN) combine high thermal conductivity with strong electrical resistance, making AlN an excellent solution for many electronic applications. Unlike most electrically insulative materials — which are often also thermally insulative — AlN allows electrical systems to dissipate heat quickly in order to maintain maximum efficiency.

Aluminum Nitride Ceramic Heater

Main Features

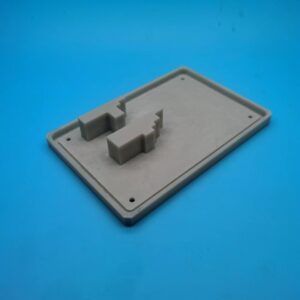

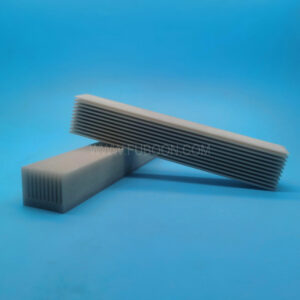

Compact ,Light-Weight and Energy-Conserving

· High watt density, good thermal efficiency

· Laying of multiple heating elements per unit is available Superior Thermal Properties

· Rapid heat increase

· Custom designed temperature distribution available

· High levels of insulation allow direct contact with water, kerosene and metal High Reliability

· Superior dielectric strength and electrical insulation

· Longer life due to oxidation-proof design on resistivity material

· Superior chemical resistance

· High watt density, good thermal efficiency

· Laying of multiple heating elements per unit is available Superior Thermal Properties

· Rapid heat increase

· Custom designed temperature distribution available

· High levels of insulation allow direct contact with water, kerosene and metal High Reliability

· Superior dielectric strength and electrical insulation

· Longer life due to oxidation-proof design on resistivity material

· Superior chemical resistance

Aluminum Nitride Ceramic Heater

Properties Sheet

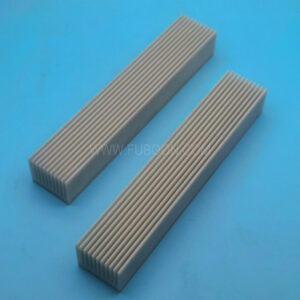

Property | Unit | Alumina Nitride Ceramic |

Color | Grey | |

Mechanical Properties | ||

Density | g/cm3 | 3.31 |

Compressive Strength | MPa | 2100 |

Flexural Strength | MPa | 335 |

Vickers Hardness | GPa | 11 |

Thermal Properties | ||

Maximum Temperature | ||

Oxidizing | °C | 700 |

Inert | °C | 1300 |

Thermal Conductivity | 30 | |

@ 25°C | W/mK | 180 |

@ 300°C | W/mK | 130 |

Coefficient of Expansion | ||

CTE 25°C ➞ 100°C | 10^-6/°C | 3.6 |

CTE 25°C ➞ 300°C | 10^-6/°C | 4.6 |

CTE 25°C ➞ 500°C | 10^-6/°C | 5.2 |

CTE 25°C ➞ 1000°C | 10^-6/°C | 5.6 |

Specific Heat | 100°C | 750 |

Thermal Shock Resistance ΔT | °C | 400 |

Electrical Properties | ||

Dielectric Constant | 1 MHz | 8.6 |

Dielectric Strength | kV/mm | >15 |

Loss Tangent | 1 MHz | 5×10^-4 |