Aluminum Nitride Conductive Substrates

Aluminum Nitride Conductive Substrates Ain Insulator Cold Ceramic Pad Sheet

- Description

- Inquiry

Aluminum Nitride Conductive Substrates

Ain Insulator Cold Ceramic Pad Sheet

| Property Sort | Property Content | Unit | Test Result |

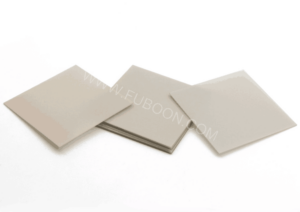

| Basic Properties | Appearance/Color | _ | Dense, Fine Crystal/off white |

| Water Absorption | % | 0 | |

| Dimensional Tolerance | mm | ≤±0.1 | |

| Thickness Tolerance | mm | ≤±0.05 | |

| Volume Density | g/cm³ | 3.3 | |

| Surface Roughness Ra | μm | 0.25~0.5 | |

| Warpage | length‰ | ≤2‰ | |

| Mechanical Properties | Flexural Strength | MPa | ≥450 |

| Modulus Of Elasticity | GPa | 320 | |

| Moh’s Hardness | MPa’m½ | 8 | |

| Electrical Properties | Volume Resistance | Ω.cm | ≥10^13 |

| Dielectric Constant | 1M Hz | 8.7 | |

| Dielectric Loss | 1M Hz | 3×10^_4 | |

| Dielectric Strength | KV/mm | ≥17 | |

| Thermal Properties | Thermal Expansivity | X10_6/℃ | 4.4 |

| Specific Heat | J/kg*k | 738 | |

| Thermal Conductivity (30℃) | W/m*k | ≥180 | |

| Regular Size | Standard thickness:0.385mm,0.5mm,0.635mm,0.75mm,1.0mm; Standard size: 50.8*50.8mm,76*76mm, 101.6*101.6mm, 114.3*114.3mm, 127*127mm, 140*190mm; Customized size and shape is available. | ||

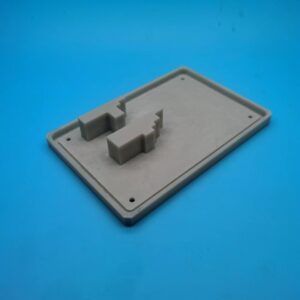

LT1800 Aluminum nitride conductive ceramic sheet has high thermal conductivity 180W/m-k,one of the highest thermal conductivity materials in metallic materials (7~10 times of alumina ceramic sheet). Excellent mechanical properties, good processing, high precision, smooth surface, no microcracks, bending, etc. Low dielectric constant and dielectric loss, reliable electrical insulation performance. Non-toxic, high temperature of 1800 degrees, oil resistant, chemical resistant, and similar to the thermal expansion coefficient of silicon, without hygroscopic property, stable performance and high reliability in high temperature and high humidity. Along with the microelectronic devices, the extensive development of the microelectronic equipment, the high thermal conductivity nitride ceramic sheet is widely valued and applied.

Aluminum Nitride Conductive Substrates