Boron carbide is smelted from boric acid and powdered carbon in electric furnace under high temperature. Depending on hardness of

4950kgf/mm2, It is even harder than diamond and cubic boron nitride. Because of their high strength, low density, corrosion

resistant, high temperature resistant, low thermal conductivity, high modulus of elasticity, it is ideal for a wide variety of

applications.Boron Carbide is one of the hardest man-made materials available in commercial quantities that has a finite melting point low

enough to permit its relatively easy fabrication into shapes. Some of Boron Carbide’s unique properties include: high hardness,

chemical inertness, and a high neutron absorbing cross section.

Boron Carbide Ceramic B4C Protective plate

- Description

- Inquiry

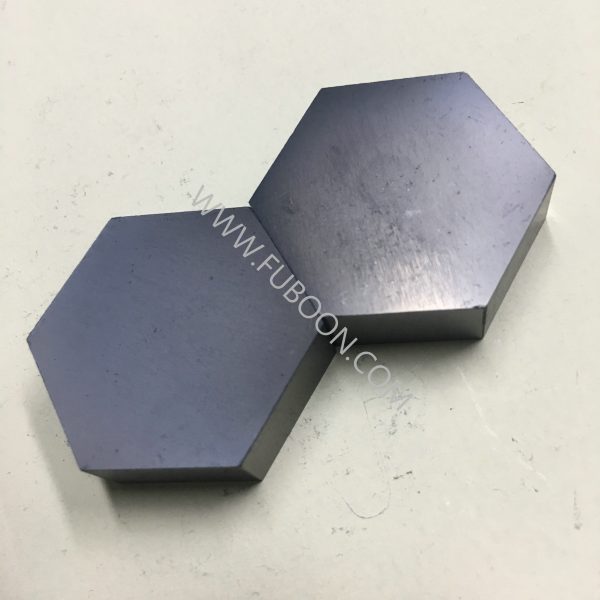

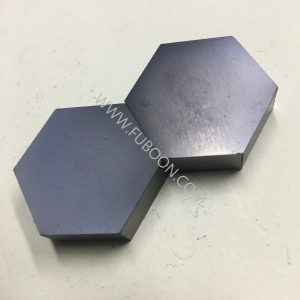

High Hardness Hexagonal Boron Carbide Ceramic B4C Protective plate

Product Description

Product Name | High Hardness Hexagonal Boron Carbide Ceramic B4C Protective Substrate |

Forming Method | Thermal casting/drying press/extrusion |

| Application | it is widely used in paints,refractory, inorganic mineral powders industries. |

Boron carbide ceramic:

Boron Carbide Ceramic B4C Protective plate

Feature:

High hardness

High modulus

High thermal conductivity

High melting point Wear resistance

High bending strength and fracture toughness

Low density

Light weight

Application:

With above performance, now many customers choose the boron carbide material used especially in body protection.

reactor neutron absorber. In addition, compared with the diamond and cubic boron nitride, boron carbide is easier to manufacture

with low cost, and therefore is is more widely used in grinding, drilling and others.

Boron Carbide Ceramic B4C Protective plate

Technical Data

Boron Carbide (B4C) Properties

Name | Unit | B4C |

Density | g/cm3 | >2.48 |

Porosity | % | <0 5 |

Vickers Hardness | HV1(GPa) | 26 |

Young’s Modulus | GPa | 410 |

Flexural Strength | MPa | 460 |

Compressive Strength | MPa | >2800 |

Fracture Toughness | MPa. m0.5 | 5 |

Coefficient of thermal expansion 25℃-500℃ 500℃-1000℃ | 10-6/K | 4.5 |

Thermal conductivity at 25℃ | W/mK | 36 |

Specific electrical resistance at 25℃ | Ω cm | 1 |