Boron carbide ceramic rod

- Description

- Inquiry

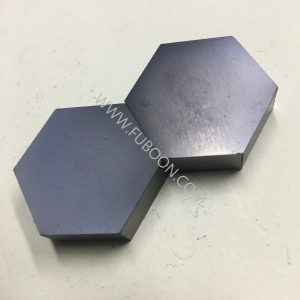

Boron carbide ceramic rod

Product Description

Boron carbide/B4C is one of the three hardest materials known (the other two are diamond and cubic boron nitride). Compared with diamond and cubic boron nitride, boron carbide is easy to manufacture and low in cost, so it is more widely used. It is widely used in individual protection, ship and other armor protection.

Material | Boron carbide/B 4C |

Features | 1. High hardness and high strength 2. Excellent thermal shock resistance 3. Excellent chemical inertness 4. Excellent wear resistance 5. Good corrosion resistance 6. High temperature resistance 7. High bending strength 8. Light weight |

Usage | 1. Grinding, polishing, lapping, drilling and crushing of hard materials such as cemented carbide and gems 2. Light weight protective armor, protection of ships and human bodies 3. Neutron shielding, neutron absorption |

Performance Index Of B4C Ceramics | ||

Type | Condition | Performance |

Main Components | Normal Temperature | B 4C≥98% |

Bulk Density g/cm 3 | Normal Temperature | 2.51 |

Elastic Modulus Gpa | Normal Temperature | 380 |

Vickers Hardness HV | Normal Temperature | 3200 |

Bending Strength Mpa | Normal Temperature | 416 |

Fracture Toughness MPa·m 1/2 | Normal Temperature | 4.38 |