Ceramic Oxygen Sensor Heater

- Description

- Inquiry

FUBOON Ceramic Oxygen Sensor Heater is suitable for use in Bosch, Denso, Delphi, NTK & NGK Oxygen Lambda Sensor, Oxygen sensors are designed to monitor the amount of oxygen that’s in the car’s exhaust stream, while ceramic heater plays an important role in the O2 sensor.

During heating, zirconia conducts oxygen ions, a characteristic that allows oxygen ions to flow from the high O2 concentration of air to the low O2 concentration on the exhaust side of the ceramic.

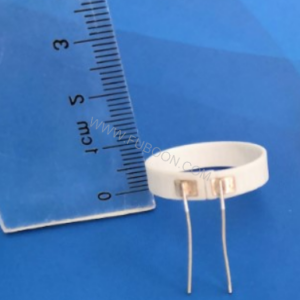

Innovacera produces ceramic heating rods and planar ceramic sensor elements, the rod shape is used for the thimble oxygen sensor and the planar ceramic heater is used for the planar oxygen sensor.

Thimble oxygen sensor cutaway:

Planar oxygen sensor cutaway:

Planar ceramic heater oxygen sensors have the below characteristics:

- Quick ignition time

- Good insulation performance

- Strong resistance to high temperature and poisoning

- Long lifetime

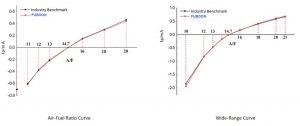

- Many types such as pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available

Planar ceramic heating element structure:

Planar ceramic heater product characteristic curve is as below:

The traditional oxygen sensor is made of alumina and inserts into a zirconia ceramic tube and commonly takes 20 seconds to activate.

New laminated planar oxygen sensor combined alumina and zirconia together, heater element was embedded in the zirconia substrate of the sensor element adopting alumina for the heater substrate material, solve the problem of low thermal conductivity of zirconia while guarantee the good heating. The new laminated planar oxygen sensor can be activated in 10 seconds after a cold start.

Ceramic Oxygen Sensor Heater

FUBOON ceramic heater applications:

1. Oxygen sensor

2. Motocycle oxygen sensor

3. Hot surface igniters (ignition of gas, oil, biomass, pellets)

4. Hot air generation

5. Tool heating

6. Melting, Welting, ordering, Hot air soldering

7. Heaters for chemical analysis and laboratory equipment (eg: min-furnaces, reactors)

8. Customer-specific heating solutions