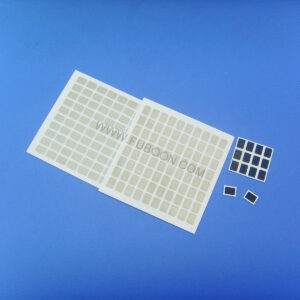

Electrical 99% Alumina Ceramic Metallized DBC Substrate

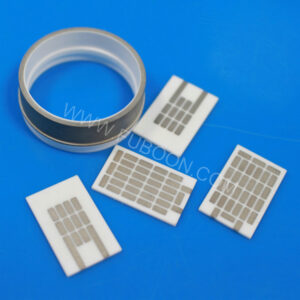

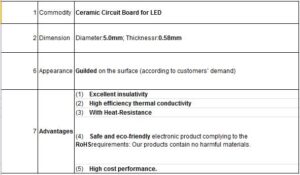

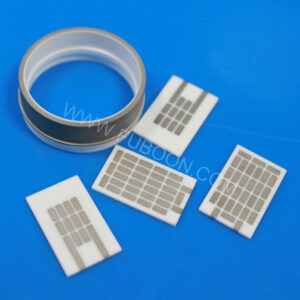

Ceramic substrates for LED

- Description

- Inquiry

Electrical 99% Alumina Ceramic Metallized DBC Substrate

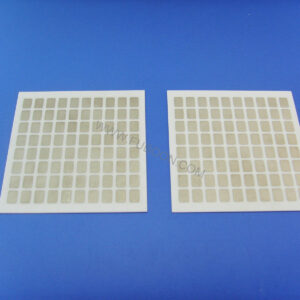

1. Thickness of substrate can be thin: 0.25mm,0.28mm,0.45mm,0.5mm,0.635mm,1.0mm,1.5mm, 1.8mm,2.0mm

2. Coating by Cu ,Mo/Mn,Ag, Plate with copper

3. Excellent thermal conductivity

4. High electrical insulation

We are producing every kind of highly qualified metallized ceramics of energy-efficient,long life and eco-friendly. There are a series of serious quality control system to make sure production quality.

Electrical 99% Alumina Ceramic Metallized DBC Substrate

DBC ceramic substrate for electronic heating devices

Direct bonded copper (DBC) substrates are commonly used in power modules, because of their very good thermal conductivity. They are composed of a ceramic tile (commonly alumina) with a sheet of copper bonded to one or both sides by a high-temperature oxidation process (the copper and substrate are heated to a carefully controlled temperature in an atmosphere of nitrogen containing about 30 ppm of oxygen; under these conditions, a copper-oxygen eutectic forms which bonds successfully both to copper and the oxides used as substrates). The top copper layer can be preformed prior to firing or chemically etched using printed circuit board technology to form an electrical circuit, while the bottom copper layer is usually kept plain. The substrate is attached to a heat spreader by soldering the bottom copper layer to it.2.Advantages of DBC ceramic substrate:

high mechanical strength

fine thermal conducticity

excellent electrical isolation

good adhesion

corrosion resistant

high reliability

environmentally clean

Alumina Ceramics Properties | |||

Unit | 95% | 99% | |

Density | g/cm3 | 3.6 | 3.8 |

Water absorption | % | <0.4 | <0.2 |

Firing temperature | °C | 1600 | 1800 |

Hardness | HRA | 70 | 80 |

Coefficientoflinearexpansion | *10-6/°C | 5.5 | 5.3 |

Dielectric constant | 9 | 10.5 | |

Volume resistivity | Ω·cm | — | 1013 |

Breakdownvoltage | KV/mm | 14 | 15 |

Breaking strength | Mpa | 250 | 300 |

Applications of DBC ceramic substrate:

semiconductor refrig-erators

power control circuits

high frequency switch mode power suppliers

solid-state relays

Solar-panel arrays

telecommunications private branch exchange and receiving system

industrial electronics

Related Products

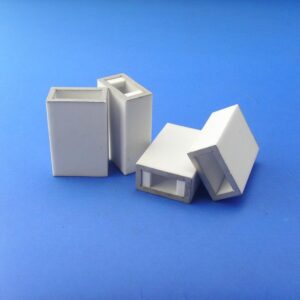

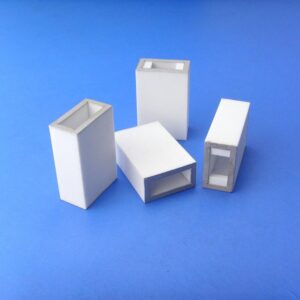

Insulating Metallized Ceramic Frame

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Alumina Metallized Ceramics for Electronic Applications

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

Metallized Ceramic Vacuum Interrupters

Metallized Ceramics for Vacuum interrupters

Alumina Al2O3 Metallizing Ceramic Part

Alumina Al2O3 Metallizing Ceramic Part

Alumina Mo-Mn Metallization

Alumina Mo-Mn Metallization/Metallized Ceramic Tube For Vacuum Electron Device

Metallized AIN Aluminum Nitride Ceramics Substrate Ni/Au Plating