Ceramic to Metal Brazing in Vacuum or Reducing Furnace

- Description

- Inquiry

Ceramic to Metal Brazing in Vacuum or Reducing Furnace

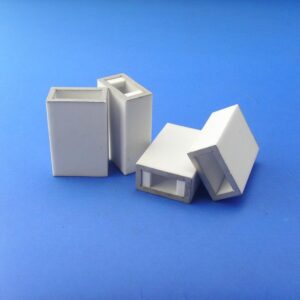

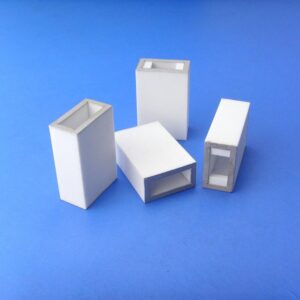

Ceramic-to-Metal brazing components are widely used in electrical engineering due to their good performance for high-vacuum, high-voltage and high-pressure applications. We manufacture a large range of metalized ceramic components with the latest technologies in order to meet the needs of our clients. Our metallizing processes could be customized according to clients’ requirements.

Material :

· Insulator-Glazed Ceramic 95% or 99% Al2O3 (white or pink)

· Feedthrugh – Nickel, Kovar, Copper

· Weld Sheath/Flange-Nickel, Kovar, 304 Stainless Steel

Features:

· Feedthroughs are custom made to specifications that determined by the electrical, temperature, and environmental condition requirements.

· Standard parts are available

Characteristics

· High Abrasion Resistance

· High Mechanical Strength

· Pressures over 10,000 PSI

· High Temperature Usage

· Low Dielectric Loss

· Mass Spectrometer Leak Tested

· High Chemical Stability

Typical Applications:

· Aerospace

· Defense Industries

· Aviation

· Medical Equipment

· Industrial Application

· Nuclear Equipment

Ceramic to Metal Brazing in Vacuum or Reducing Furnace

Product Description

Major components | 95% 96%.99 Al2O3 | |||

Density | g/cm3 | 3.6 | ||

Material properties | Water absorption | % | O | |

Sintering temperature | °C | 1600-1800 | ||

Physical properties | Hardness | HV | 1500 | |

Flexural strength | Kgf/cm2 | 3000 | ||

Compressive strength | Kgf/cm2 | 25000 | ||

Fracture toughness | Map.m3/2 | 3-4 | ||

Maximum temperature | °C | 1800 | ||

Thermal properties | Coefficient of thermal expansion | /°C | 8*10-6 | |

Heat shock | T(°C) | 220 | ||

Thermal conductivity | W/m.k(25-300°C) | 25 14 | ||

20°C | >1012 | |||

Volume resistivity | 100°C | >.cm | 1012-1013 | |

Electrical Characteristics | 300°C | >1010 | ||

Insulation breakdown strength | KV/mm | 18 | ||

dielectric constant | 100MHz(E) | 9.5 | ||

| Applications: | |

| Feed-through insulators | Power switches |

| Insulating discs | Traveling wave tubes |

| Insulator rings and cylinders | Vacuum interrupters |

| Headers | Windows |

| High-power receptacles | Power grid tubes |

| Precipitator products | X-ray tubes |

| Joining types: |

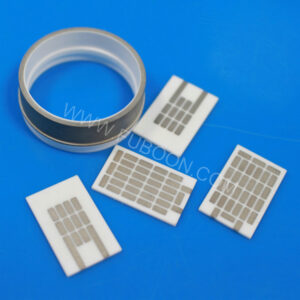

| Ceramic + Mo/Mn Metallized + plating Ni |

| Ceramic + Mo/Mn Metallized + plating Ag |

| Ceramic + Mo/Mn Metallized + plating Au |

| Ceramic + printing Ag |

| * Special types are available according to customer’s drawings or samples. |

Related Products

Metallized Ceramic Alumina Insulator for Brazing

Alumina Al2O3 Metallizing Ceramic Part

Alumina Al2O3 Metallizing Ceramic Part

Alumina Mo-Mn Metallization

Alumina Mo-Mn Metallization/Metallized Ceramic Tube For Vacuum Electron Device

Metallized Al2O3 Ceramics Substrate Ni/Au Plating

Metallized Ceramic Tube Vacuum Feedthrough Insulator

Metallized Ceramic Tube For Vacuum Feedthrough Insulator

Metallized Ceramic Components for Kovar Brazing

Alumina Metallized Ceramics for Electronic Applications

Metallized AIN Aluminum Nitride Ceramics Substrate Ni/Au Plating

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube