CNC Aluminium Nitride Ceramic Components

- Description

- Inquiry

CNC Aluminium Nitride Ceramic Components

Aluminum Nitride (AlN) is an excellent material to use if high thermal conductivity and electrical insulation properties are required; making it an ideal material for use in thermal management and electrical applications. Additionally, AlN is a common alternative to Beryllium Oxide (BeO) in the semiconductor industry as it is not a health hazard when machined.

Aluminum Nitride has a coefficient of thermal expansion and electrical insulation properties that closely matches that of Silicon wafer material, making it an useful material for electronics applications where high temperatures and heat dissipation is often a problem.

Aluminum Nitride is one of the few materials that offers electrical insulation and high thermal conductivity. This makes AlN extremely useful in high power electronic applications in heat sink and heat spreader applications.

Aluminum Nitride Machining Precision Ceramics is your Aluminum Nitride machining specialist for your technical ceramic prototyping & manufacturing needs.

Aluminum Nitride can be machined in green, biscuit, or fully dense states. While in the green or biscuit form it can be machined relatively easily into complex geometries. However, the sintering process that is required to fully densify the material causes the Aluminum Nitride body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining AlN pre-sintering.

In order to achieve very tight tolerances, fully sintered material must be machined/ground with diamond tools. In this process a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherent toughness and hardness of the material, this can be a time consuming and costly process.

AlN commonly comes in substrates up to 1 mm thick which can easily be laser cut. It can also come in thicker forms, however, it can be difficult/costly to manufacture in small quantities if the part requires custom material or significant machining.

Aluminum Nitride (AlN) is an excellent material to use if high thermal conductivity and electrical insulation properties are required. Because of it’s qualities, it is an ideal material for use in thermal management and electrical applications.

CNC Aluminium Nitride Ceramic Components

Some common applications of Aluminum Nitride include the following:

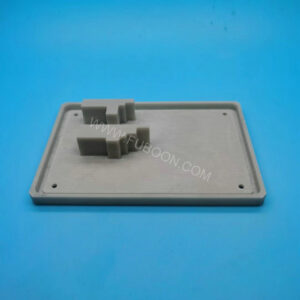

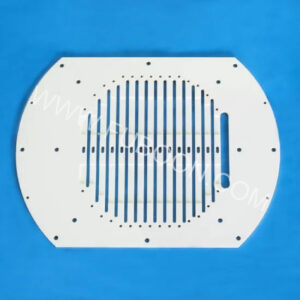

Heat sinks & heat spreaders

Electrical insulators for lasers

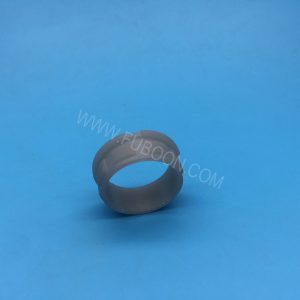

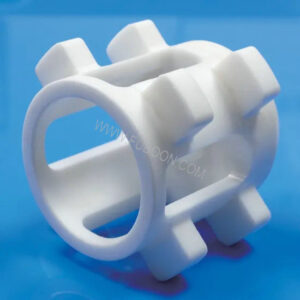

Chucks, clamp rings for semiconductor processing equipment

Electrical insulators

Silicon wafer handling and processing

Substrates & insulators for microelectronic devices & opto electronic devices

Substrates for electronic packages

Chip carriers for sensors and detectors

Chiplets

Collets

Laser heat management components

Molten metal fixtures

Packages for microwave devices

Property | Unit | Alumina Nitride Ceramic |

Color | Grey | |

Mechanical Properties | ||

Density | g/cm3 | 3.31 |

Compressive Strength | MPa | 2100 |

Flexural Strength | MPa | 335 |

Vickers Hardness | GPa | 11 |

Thermal Properties | ||

Maximum Temperature | ||

Oxidizing | °C | 700 |

Inert | °C | 1300 |

Thermal Conductivity | 30 | |

@ 25°C | W/mK | 180 |

@ 300°C | W/mK | 130 |

Coefficient of Expansion | ||

CTE 25°C ➞ 100°C | 10^-6/°C | 3.6 |

CTE 25°C ➞ 300°C | 10^-6/°C | 4.6 |

CTE 25°C ➞ 500°C | 10^-6/°C | 5.2 |

CTE 25°C ➞ 1000°C | 10^-6/°C | 5.6 |

Specific Heat | 100°C | 750 |

Thermal Shock Resistance ΔT | °C | 400 |

Electrical Properties | ||

Dielectric Constant | 1 MHz | 8.6 |

Dielectric Strength | kV/mm | >15 |

Loss Tangent | 1 MHz | 5×10^-4 |