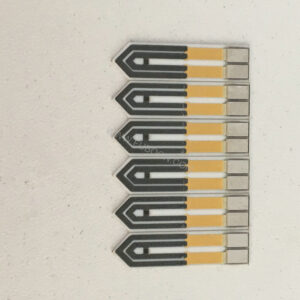

Electronic soldering iron ceramic heater

Ceramic heater for electronic soldering iron

- Description

- Inquiry

Electronic soldering iron ceramic heater

soldering iron heater design with long life, energy-efficient and eco-friendly. There are a series of serious quality control system to make sure production quality.

Mass customization is availableCeramic heater for electronic soldering iron

Ceramic Heater Alumina Information

Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before.Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries.

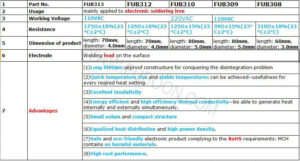

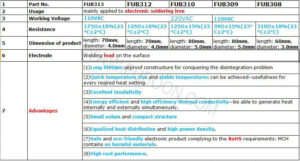

More Specification for reference:

Application: Mainly applied to electronic soldering iron

Voltage: 110VAC

Heating Resistance: 175Ω±10%

Dimension: L70*φ4.0mm

Electrode: Welding 2 nickel wires on the surface

More Specification for reference:

Application: Mainly applied to electronic soldering iron

Voltage: 110VAC

Heating Resistance: 175Ω±10%

Dimension: L70*φ4.0mm

Electrode: Welding 2 nickel wires on the surface

Application: Mainly applied to electronic soldering iron

Voltage: 110VAC

Heating Resistance: 310Ω±10%

Dimension: L60*φ3.8mm

Electrode: Welding 2 nickel wires on the surface

Voltage: 110VAC

Heating Resistance: 310Ω±10%

Dimension: L60*φ3.8mm

Electrode: Welding 2 nickel wires on the surface

Advantage

—

1.Small volume,compact structure and long service life.

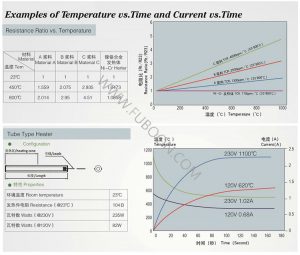

2.Energefficient,super fast heating-up and high efficient thermal conductivity.

3.Excellent insulation and dielectric strength.

4.Sensor resistance is liner changing along with the temperature rising of heater.

5.Good sensitivity.

6.Safe product which contains no harmful material,i.e.be in line with intermatioal environmental protection standards.

3.Excellent insulation and dielectric strength.

4.Sensor resistance is liner changing along with the temperature rising of heater.

5.Good sensitivity.

6.Safe product which contains no harmful material,i.e.be in line with intermatioal environmental protection standards.

Application

—

We are producing High Quality Hakko A1321 24V 60W Heating Element for 936 Soldering Station with the advantages of

energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Dimension for reference

—

Part No. | Specification(mm) | Voltage | Heating Resistance |

AH60790301 | L60*φ3.8mm | 24VAC | 3.0±0.3 |

AH60790364 | L60*φ3.8mm | 220VAC | 140±10% |

AH60790331 | L60*φ4.3mm | 24VAC | 1.75±0.25 |

AH60790308 | L60*φ3.8mm | 110VAC | 310Ω±10% |

AH60790312 | L70*φ4.0mm | 110VAC | 125Ω±10% |

AH60790313 | L70*φ4.0mm | 110VAC | 175Ω±10% |

AH60790309 | L80*φ5.0mm | 100VAC | 37Ω±15% |

Electronic soldering iron ceramic heater