FUQD-R Series Ceramic Pump Integration

- Description

- Inquiry

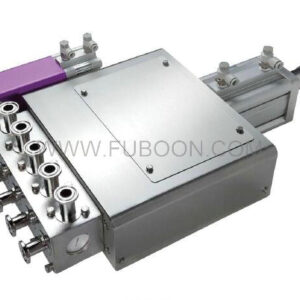

FUQD-R Series Ceramic Pump Integration

QD-R Series Ceramic Pump Integration adopts a precision ceramic plunger design, which is suitable for medium and high

viscosity liquids, creams, and creams (1000-100,000CPS) and containing particle materials.

Ceramic Pump Integration

Features:

1.The motor adjusts the filling volume, so that the pump has high metering accuracy and repeat consistency, and the accuracy is better than +0.5%.

2.The metal part of the contact material is made of 316L stainless steel, which has better corrosion resistar

3.The pump body is connected in a quick-disassembly mode, which is convenient for disassembly, assembly, and cleaning.and meets the cleaning requirements of food hygiene standards.

lndustry application:

lt can be used for the matching and transformation of the filling part of the packaging machine. It is very suitable for filingcream, honey, electrolyte, liquid medicine , biochemical reagent, chemical liquid, the essence, medium and high viscosityhomogeneous liquid materials such as oils, essences, lotions, perfumes, nail polish, etc.

Product Advantages:

* Made of high-purity alumina powder imported from Australia, the pumps enjoy the superior properties of high hardness, wear-resistance, heat-resistance, corrosion-resistance;

* Advanced polishing and forming method to get beteter micro porosity, which can play an important role in self lubricating;

* Good surface polish to form a smooth entocoel to easier the disinfecting and washing operation;

* we can produce customized pumps according to different requirements.

* Research institutes, laboratories, universities, laboratories, hospitals, factories and other cosmetics.

* Widely used in medicine, pharmaceutical, food, chemcial, cosmetics and other industries precise

* For blood, biological reagents, oral, injection, senior cosmetics, fragrances, fungicides and other liquid quantitative filling precision.

* Various chemical corrosive liquid quantitative filling precision

| Model | FUQD-R04 | FUQD-R12 | FUQD-R25 | FUQD-R50 | FUQD-R100 | FUQD-R300 |

| Materials | Ceramic parts:Al2O3,ZrO2 or Silicon carbide | |||||

| Metal parts:316L,Buttom:304 | ||||||

| Filling range | 0.4-4ml | 1-12ml | 2-25ml | 5-50ml | 10-100ml | 30-300ml |

| Air pressure | 0.4-0.6Mpa | |||||

| Filling accuracy | ±0.5%-0.8% | |||||

| Hopper capacity | 5L | 10L | 10L | 10L | 20L | 20L |