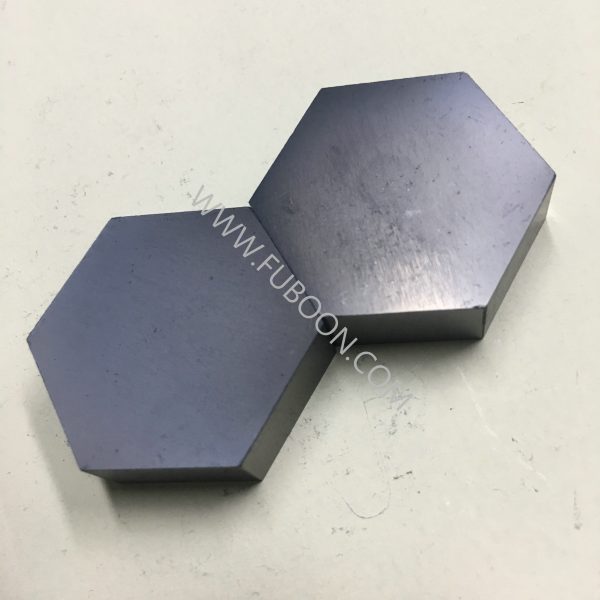

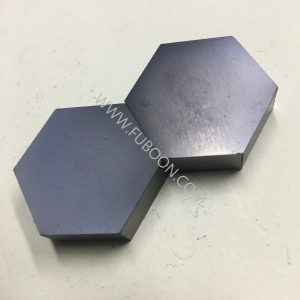

Hexagonal Boron Carbide Ceramic Armor Plate

- Description

- Inquiry

Hexagonal Boron Carbide Ceramic Armor Plate B4C

– Material: | B4C / Boron Carbide |

– Introduction: | Boron carbide (B4C) is one of the world’s hardest manufactured materials. Its strong chemical bonds and hard surface minimize wearin rigorous environments. Boron carbides are often used in ballistic armor, taking advantage of exceptional hardness and lowdensity. The hardness provides excellent protection, while the light-weight maximizes mobility. Additionally, the uniquely structured boron carbide can be used for neutron shielding. |

– Typical Characteristics: | 1. Exceptional Hardness 2. Out Standing Wear Resistance 3. Low Density 4. High Flexural Strength 5. Neutron Absorbing |

– Typical Applications: |

Properties / Material | Boron Carbide (B4C) |

Sintering Method | Hot Pressing |

Density (g/cm3) | 2.50 |

Hardness HV (MPa) | 3200 |

Flexural Strength (MPa) | 480 |

Boron Carbide Ceramic Armor Plate

B4c powder (also known as black diamond) is the third hardest material after diamond and cubic boron nitride. It is a suitable material for many high performance applications due to its attractive combination of properties. Its outstanding hardness makes it a suitable abrasive powder for lapping, polishing and water jet cutting of metals and ceramics. The combination of low specific weight, high hardness and reasonable toughness makes it a suitable material for body and vehicle armor. Boron carbide is also extensively used as control rods, shielding materials and as neutron detectors in nuclear reactors due to its ability to absorb neutrons without forming long lived radionuclide. As it is a p-type semiconductor, boron carbide can be a suitable candidate material for electronic devices that can be operated at high temperatures. Boron Carbide is also an excellent p-type thermoelectric material.

Boron Carbide Properties

High hardness

Low density

High melting point

High elastic modulus

Chemical inertness

High neutron absorption cross-section

Excellent thermoelectric properties

Boron Carbide Applications

Sand blasting nozzles

Ball & roller bearings

Seals

Wire drawing dies

Body armor

Boron Carbide Machining & Grinding

Boron Carbide Ceramic Armor Plate

Boron Carbide can be machined in green, biscuit, or fully dense states. While in the green or biscuit form it can be machined relatively easily into complex geometries. However, the sintering process that is required to fully densify the material causes the Boron Carbide body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining Boron Carbide pre-sintering. In order to achieve very tight tolerances, fully sintered material must be machined/ground with diamond tools. In this process a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherit hardness of the material, this can be a time consuming and costly process.

Usage of Boron Carbide

1.For making high performance Abrasive Tools

2.For processing and grinding Sapphier Crystal Plate

3.For making Refractories such as Magnesia Carbon Bricks etc.

4.For making Ceramics such as Nozzles, Ring Seals, Mould etc.

5.For making Nozzles of gun and artillery

6.As Bulletproof Materials for making Bulletproof Vests,Tiles

7.As Neutron Absorber in Nuclear Industry