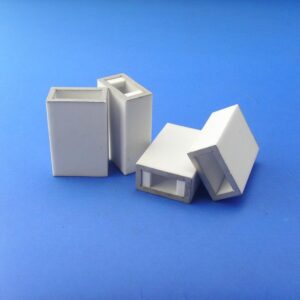

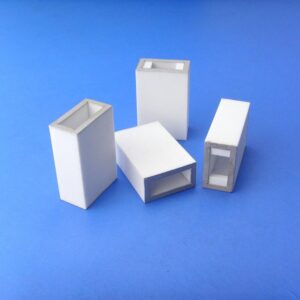

Insulating Metallized Ceramic Frame

Categories: Metallized Ceramics Tags: Insulating Metallized Ceramic Frame

- Description

- Inquiry

Features

1) High-intensity sealing, high air-tightness, high reliability, good heat resistance

2) Excellent insulation performance and high temperature resistance

3) Good mechanical , electrical and thermal conductivity

4) Great bonding strength

5) Widely used for all electric products and electric heating products

1) High-intensity sealing, high air-tightness, high reliability, good heat resistance

2) Excellent insulation performance and high temperature resistance

3) Good mechanical , electrical and thermal conductivity

4) Great bonding strength

5) Widely used for all electric products and electric heating products

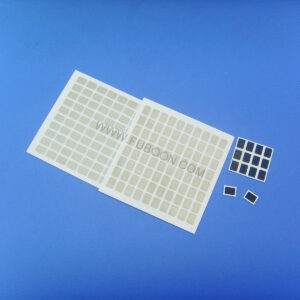

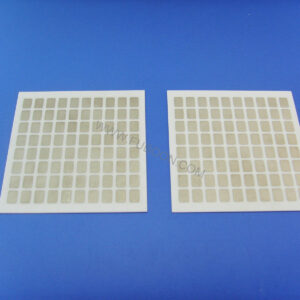

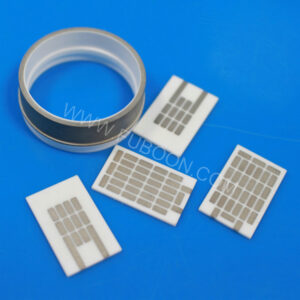

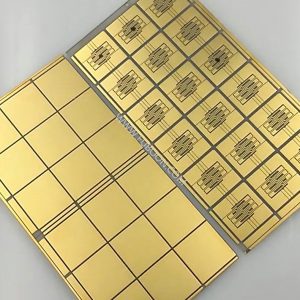

Insulating Metallized Ceramic Frame

1.Material: 96% Aluminia(AL2O3)

2.Coating Layer:Molybdenum-Mananese(Mo/Mn)

3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos.

2.Coating Layer:Molybdenum-Mananese(Mo/Mn)

3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos.

So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing. A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a differentcoefficient of thermal expansion.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Applications:

Electrical transmission and distribution

Electronics industry

Textile machinery

Defense

Medical electronics

Automobile industry

Sealing

Solid Oxide Fuel Cells

High temperature application

We can supply the products according to customer’s drawings, samples and performance requirement.

metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components,ceramic metallizing, welding ceramic part.

Electronics industry

Textile machinery

Defense

Medical electronics

Automobile industry

Sealing

Solid Oxide Fuel Cells

High temperature application

We can supply the products according to customer’s drawings, samples and performance requirement.

metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components,ceramic metallizing, welding ceramic part.

Related Products

Electrical 99% Alumina Ceramic Metallized DBC Substrate

Ceramic substrates for LED

Metallized Ceramic Vacuum Interrupters

Metallized Ceramics for Vacuum interrupters

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Alumina Mo-Mn Metallization

Alumina Mo-Mn Metallization/Metallized Ceramic Tube For Vacuum Electron Device

Alumina Al2O3 Metallizing Ceramic Parts

Alumina Al2O3 Metallizing Ceramic Parts

High Temperature Resistance Alumina Metallized Ceramic Ring

High Temperature Resistance Alumina Metallized Ceramic Ring

Metallized Ceramic Components for Kovar Brazing

AlN Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

Alumina Al2O3 Metallizing Ceramic Part

Alumina Al2O3 Metallizing Ceramic Part