Low Voltage Ceramic Heating Element for Vaporizer

Low Voltage Ceramic Heating Element for Herb Vaporizer/Atomizer

- Description

- Inquiry

Low Voltage Ceramic Heating Element for Vaporizer

Low Voltage Ceramic Heating Element for Herb Vaporizer Atomizer

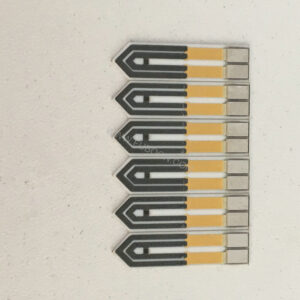

MCH Ceramic Heating Element is produced by implementing unique metallization and ceramic lamination

Specification: | ||

Dimension | OD7*T0.6 | Resistance range(Ω): 0.4-0.6 |

OD11*T0.8 | Resistance range(Ω): 0.3-0.4 | |

OD24*T1.2 | Resistance range(Ω): 3.7-4.5/10-13/16-22/9-11/11.3-13.7 | |

OD20*T1.2 | Resistance range(Ω): 17-20/7.5-8.8/1.5-2.0 | |

OD14*T1.2 | Resistance range(Ω): 95-101/70-84/110-145/200-290/140-170/25.5-30.5/25-33/270-330/100-120 | |

OD30*T1.2 | Resistance range(Ω): 1.4-1.69/0.8-1.1/12-16/4-5/1.7-2.1/2.53-2.77/2.0-2.53/2.5-2.8 | |

OD38*T1.2 | Resistance range(Ω): 2.0-2.59/450-550/2.5-3.2/5-6/2.6-3.2 | |

Rated Voltage | 5V, 12V, 24V ( all can be customized ) | |

Application | Heating Hemp, Moxibustion, Medical Device, Coffee Machine, Car Water Heatet Up … … | |

FUBOON International is a professional ceramic resistor heating tube for E-cigarette/herbal vaporizer Heater 0~250C/Amomizer Heater/Vaporizer Heater/Herb Heater manufacturer with manyyears export and more. You can customised your products here according to your drawings, samples and performance requirement.

Ceramic Heating Element for Vaporizer

Specifications

Ceramic resistor Atomizer heater which working temperature from 0~250C suitable for E-Cig, herb atomizer/vaporizer/Herb Vaporizer.

It enjoys great advantages of its compact size, light weight, energy saving and long life time.

Ceramic Heating Element for Herb Vaporizer/Atomizer

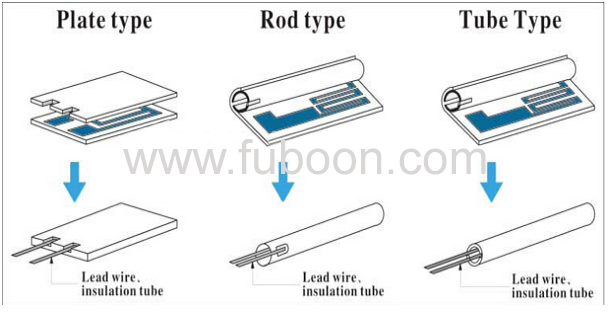

Ceramic Heating plates Usual Specification:

Dimension: accordingly

Voltage: 3.7V-230V

Resistance: accordingly

Dielectric strength: 3750V, 5s, Leakage current ≤ 0.5mA

Flexural strength: ≥300Mpa

Ceramic resistor heater used for Vaporizer of E-Cig heater/Atomizer/Herb heating. It is applicable to a variety of herb heating vaporizer product because moderate temperature distribution can be obtained by the heater design.

Alumina (Al2O3) is a hard-wearing technical ceramic material frequently used in a broad range variety of industries applications. After firing and sintering, the alumina ceramic parts can only be precisely machined using diamond-grinding methods. It’s charactered by high tighten tolerance, high hardness and wear resistance, low erosion levels, high-temperature resistance, corrosion resistance, and chemical stability. Furthermore, it can be highly polished making it a mirror surface to reduce friction at the fitting, working status.