Magnesium Stabilized Zirconia Ceramics (MSZ)

- Description

- Inquiry

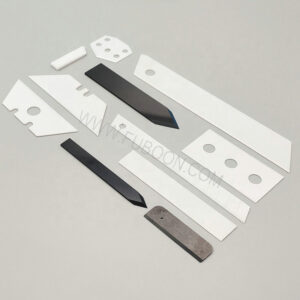

As an advanced ceramic material, magnesium-stabilized zirconia ceramic (MSZ) has the characteristics of high melting point, high hardness, excellent wear resistance, high toughness, good thermal stability, corrosion resistance and high strength. It has wide application prospects in the fields of aerospace, energy, medical equipment, and electronics, providing new possibilities for the development of modern science and technology.

Basic characteristics of zirconia ceramics

Zirconia ceramic is a ceramic material with high melting point, high hardness, and excellent wear resistance. It has the following basic characteristics:

1) High melting point: The melting point of zirconia ceramic is as high as 2700°C, giving it excellent stability in high temperature environments.

2) High hardness: Zirconia ceramic has extremely high hardness and can resist scratches and wear, maintaining its long-term stability.

3) Excellent wear resistance: Zirconia ceramic has excellent wear resistance, allowing it to perform well in various harsh environments.

- Advantages of Magnesium Stabilized Zirconia Ceramics (MSZ)

Magnesium-stabilized zirconia ceramics (MSZ) are based on zirconia ceramics, and their performance is further improved by adding an appropriate amount of magnesium stabilizer. Magnesium stabilized zirconia ceramics (MSZ) have the following advantages:

- High toughness

- Good thermal stability

- Excellent corrosion resistance

- High strength

- Application of magnesium-stabilized zirconia ceramics (MSZ) in the field of modern science and technology

The following are the applications of magnesium stabilized zirconia ceramics (MSZ) in different fields:

1) Aerospace

2) Energy

3) Medical devices

4) Electronics

- Materials Propertiesof magnesium-stabilized zirconia ceramics (MSZ)

| Item | Properties | Unit | Value |

| Color | Ivory / Gray-White | ||

| Mechanical Properties | Density | g/cm3 | 5.70-5.75 |

| Vickers hardness | Gpa | 11-12 | |

| Three point bending strength | Mpa | 500 | |

| Fracture toughness KIC | Mpa•m1/2 | 6-10 | |

| Thermal properties | Thermal conductivity | W/mK | 2-3 |

| Thermal expansion coefficient | 1×106/℃ | 10 | |

| Thermal shock temperature | ℃ | 350 | |

| Maximum operating temperature | ℃ | 1000 |