Metallized Ceramic Components for Kovar Brazing

- Description

- Inquiry

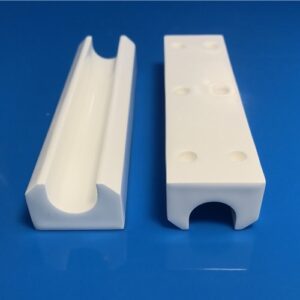

Metallized Ceramic Components

Material : 96.0% alumina or 99.5% high purity alumina with Metalization treatment

– Either Cold Isostatic Press or dry press formed bodies with secondary fine-machining

– High precision and good appearance after metalization

– Easy for brazing with Kovar alloy directly

– High bonding strength after brazing with kovar parts

– Good insulation, anti-magnetic, static electricity-free character for feedthrough use

– Excellent thermal shock resistance and good thermal stability after brazing

– Outstanding bending strength and toughness

– Anti corrosion & abrasion resistance in harsh working environments

– Professional ceramic R&D team is available for your requests of various metallized ceramic parts

Product Name | Custom Industrial Metallized Ceramic Components for Kovar Brazing with Tight Hermetic Sealing |

Compositions | 96.0% alumina or 99.5% high purity alumina (Al2O3) |

Metalization | Sintered with Molybdenum & Manganese (Mo+Mn), then Nickel plating |

Mo+Mn Layer | 25 +/-10μm in thickness |

Nickel Layer | 2 -10μm in thickness |

Material Density | 3.90 g/cm3 |

Tolerance | +/- 0.005mm |

Finishing | Ra 0.02 |

Max. Using Temperature | 1650 oC |

Using Fields | Feedthrough, Fuel cell, PVD or CVD machines, Power Staions, Semi conductors, Electronics Equipments, Aerospace |

Metallized Ceramic Components

Kovar Alloy Chemical Compositions Sheet | ||||

Elements | Symbol | YB/T 5231 | ASTM F15 | DIN 17745 |

4J29 | K94610 | 1.3981 | ||

Carbon | C | ≤0.03 | ≤0.04 | ≤0.05 |

Silicon | Si | ≤0.30 | ≤0.20 | ≤ 0.30 |

Manganese | Mn | ≤0.50 | ≤0.50 | ≤0.50 |

Phosphorus | P | ≤0.020 | – | – |

Sulphur | S | ≤0.020 | – | – |

Nickel | Ni | 28.5~29.5 | 29.0* | 28.0~30.0 |

Cobalt | Co | 16.8~17.8 | 17.0* | 16.0~18.0 |

Chromium | Cr | ≤0.20 | ≤0.20 | – |

Copper | Cu | ≤0.20 | ≤0.20 | – |

Molybdenum | Mo | ≤0.20 | ≤0.20 | – |

Aluminum | Al | – | ≤0.10 | – |

Magnesium | Mg | – | ≤0.10 | – |

Zirconium | Zr | – | ≤0.10 | – |

Titanium | Ti | – | ≤0.10 | – |

Iron | Fe | Balance | 53.0* | Rest |

*:norminal valves, they should be adjusted by the manufacturer so that the alloy meet the requirement for CTE in different temperature range | ||||

Related Products

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

Electrical ceramic insulators

ceramic insulators for heaters electrical ceramic insulators

Alumina Ceramic precision ball

Alumina Ceramic precision ball for bearing

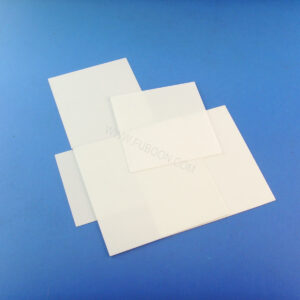

Al2O3 Ceramic Substrate

Al2O3 Ceramic Substrate for electronics

Alumina liner tube sleeve cylinder for pump

Alumina liner tube/sleeve/cylinder for pump

High Purity Heat Resistant Alumina Ceramic Tube

Precision alumina ceramic tube

Al2O3 Ceramic Steel Shaft

Alumina Al2O3 Ceramic Steel Shaft

Alumina Ceramic Bushing Sleeve Tubes

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

Al2o3 ceramic shaft piston plunger

Al2o3 ceramic shaft piston plunger

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector