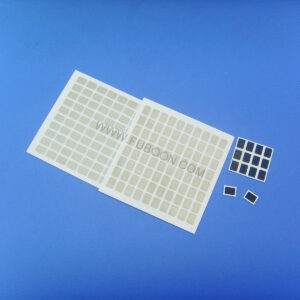

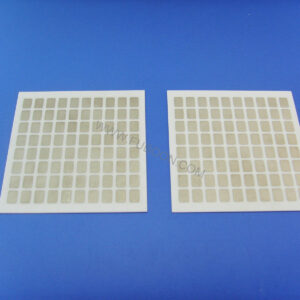

Mo Mn Metallized Electrical Ceramic Insulator

- Description

- Inquiry

Mo Mn Metallized Electrical Ceramic Insulator

Ceramic-to-Metal brazing components are widely used in electrical engineering due to their good performance for high-vacuum, high-voltage and high-pressure applications. We manufacture a large range of metalized ceramic components with the latest technologies in order to meet the needs of our clients. Our metallizing processes could be customized according to clients’ requirements.

Material :

· Insulator-Glazed Ceramic 95% or 99% Al2O3 (white or pink)

· Feedthrugh – Nickel, Kovar, Copper

· Weld Sheath/Flange-Nickel, Kovar, 304 Stainless Steel

Features:

· Feedthroughs are custom made to specifications that determined by the electrical, temperature, and environmental condition requirements.

· Standard parts are available

Characteristics

· High Abrasion Resistance

· High Mechanical Strength

· Pressures over 10,000 PSI

· High Temperature Usage

· Low Dielectric Loss

· Mass Spectrometer Leak Tested

· High Chemical Stability

Typical Applications:

· Aerospace

· Defense Industries

· Aviation

· Medical Equipment

· Industrial Application

· Nuclear Equipment

Mo Mn Metallized Electrical Ceramic Insulator

Major components | 95% 96%.99 Al2O3 | |||

Density | g/cm3 | 3.6 | ||

Material properties | Water absorption | % | O | |

Sintering temperature | °C | 1600-1800 | ||

Physical properties | Hardness | HV | 1500 | |

Flexural strength | Kgf/cm2 | 3000 | ||

Compressive strength | Kgf/cm2 | 25000 | ||

Fracture toughness | Map.m3/2 | 3-4 | ||

Maximum temperature | °C | 1800 | ||

Thermal properties | Coefficient of thermal expansion | /°C | 8*10-6 | |

Heat shock | T(°C) | 220 | ||

Thermal conductivity | W/m.k(25-300°C) | 25 14 | ||

20°C | >1012 | |||

Volume resistivity | 100°C | >.cm | 1012-1013 | |

Electrical Characteristics | 300°C | >1010 | ||

Insulation breakdown strength | KV/mm | 18 | ||

dielectric constant | 100MHz(E) | 9.5 | ||

| Applications: | |

| Feed-through insulators | Power switches |

| Insulating discs | Traveling wave tubes |

| Insulator rings and cylinders | Vacuum interrupters |

| Headers | Windows |

| High-power receptacles | Power grid tubes |

| Precipitator products | X-ray tubes |

| Joining types: |

| Ceramic + Mo/Mn Metallized + plating Ni |

| Ceramic + Mo/Mn Metallized + plating Ag |

| Ceramic + Mo/Mn Metallized + plating Au |

| Ceramic + printing Ag |

| * Special types are available according to customer’s drawings or samples. |

Related Products

Metallized Al2O3 Ceramics Substrate Ni/Au Plating

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Alumina Al2O3 Metallizing Ceramic Parts

Alumina Al2O3 Metallizing Ceramic Parts

Aluminum Nitride AlN Metallized DBC Substrate/Plate/Disc with Au

High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

Electrical 99% Alumina Ceramic Metallized DBC Substrate

Ceramic substrates for LED

Insulating Metallized Ceramic Frame

Metallized AIN Aluminum Nitride Ceramics Substrate Ni/Au Plating

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

Metallized Ceramic Tube Vacuum Feedthrough Insulator

Metallized Ceramic Tube For Vacuum Feedthrough Insulator