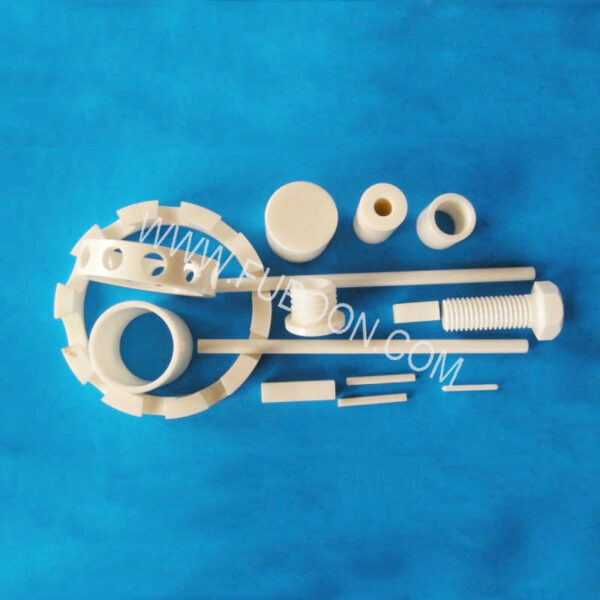

Multi Types Precision Advanced Ceramic Spare Part Components

- Description

- Inquiry

Multi Types Precision Advanced Ceramic Spare Part Components

Materials: Alumina (Al2O3),Zirconia(ZrO2),Si3N4,SiC

Ceramic parts and components accessories refer to mechanical parts made of special ceramic materials through mixing, molding, sintering and processing procedures.

Manufacturing parameters:

| Additional Information: ·In stock items will typically ship in a few working days. ·Unit price and estimated ship dates will be calculated when the length and quantity are specified. ·Diameter tolerance ± 3% or ± 0.003″ (0.076 mm), Straightness: ≤ 0.003″/1.000″ cumulative. ·Can be customized Customization: As a manufacturer of ceramic parts, we offer customization of ceramic special sizes and shapes.High Precision, Fast Delivery Time, High Composition (with test report). Lead time: 2-25 working days for the mass with free sample of mass ; Minimum order quantity : 1 qty | |||||||||||||||||||||||||||||

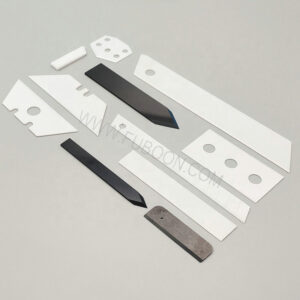

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC …etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm… etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation…

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

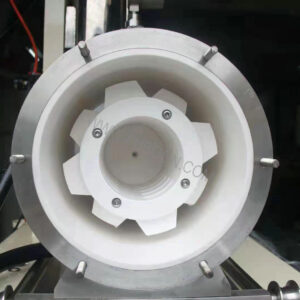

Ceramic applications:

automotive, aviation, space travel

electrical and thermal insulation

electronics and sensors

energy technology, power generation

environmental technology

fluid technology

friction-reduction, wear- and corrosion -protection

high temperature applications

laboratory technology

laser technology

mechanical and chemical process engineering

metal industry

optics

semiconductor processing equipment

surface treatment

vacuum technology

Features:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)…

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1….

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm…

4. High Polished Surface Up To Rz0.8(Ra0.1) …

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength…

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance…

8. Long Service Life…

9. Other excellent property

Ceramic material composition:

· 95%–99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

…

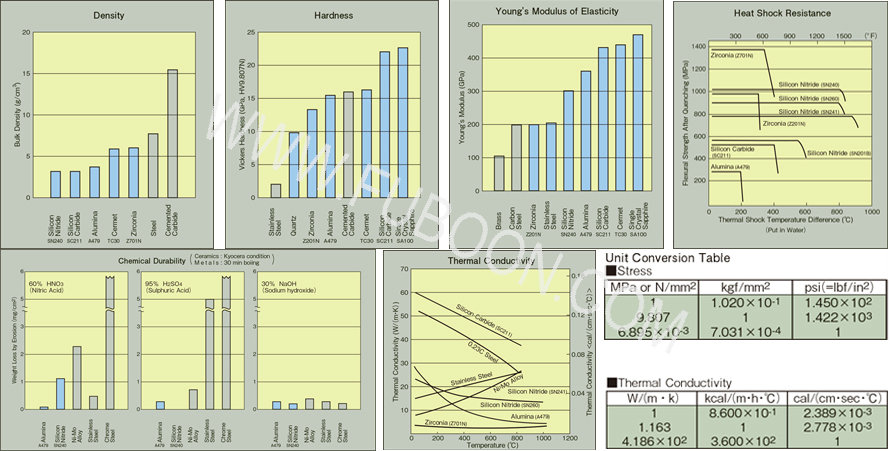

The properties of ceramic:

·Excellent physical & chemical stability ·High temperature resistance

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity…

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Tensile strength | MPa | 248 | 250 | / | / |

As a manufacturer of ceramic parts, we offer customization of ceramic for special sizes and shapes.High Precision, Fast Delivery Time, High Composition.