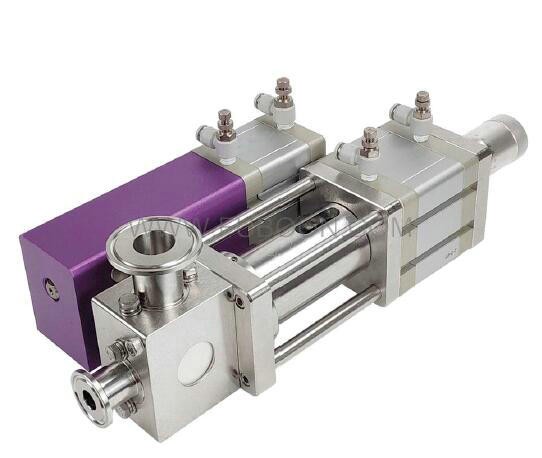

Pneumatic Ceramic plunger pump

FUHB Series Pneumatic Ceramic plunger pump

- Description

- Inquiry

Pneumatic Ceramic plunger pump

FUHB Series

| Model | FUHB-10 | FUHB-20 | FUHB-50 | FUHB-100 |

| Ceramic material | Al2O3&ZrO2 | Al2O3&ZrO2 | Al2O3&ZrO2 | Al2O3&ZrO2 |

| Filling range | 1-10ml | 2-20ml | 5-50ml | 10-100ml |

| Air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Filling accuracy | 0.5%-0.8% | 0.5%-0.8% | 0.5%-0.8% | 0.5%-0.8% |

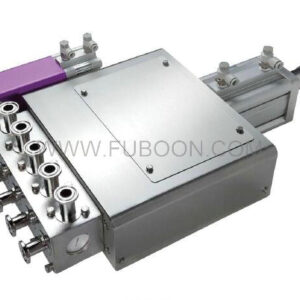

Multi-column

| Model | FUHBS-10-5 | Others |

| Filling range | 1-10ml | As requirement |

| Qty. of Pump | 5sets | 2sets to 4sets |

| Ceramic material | Al2O3&ZrO2 | Al2O3&ZrO2 |

| Weight | 22kgs | According to actual |

| Air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Dimensions | 545*310*115mm | According to actual |

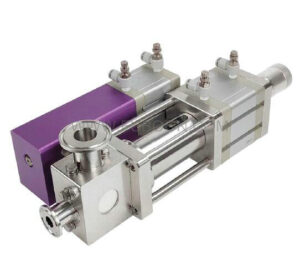

The FUHB series ceramic plunger pneumatic pump adopts a precision ceramic plunger design and a closed rotary valve linkage system. It has a more compact structure and can meet application scenarios with higher requirements for equipment volume. It is suitable for medium and high viscosity. Homogeneous liquids, creams (1000-100,000CPS) and quantitative perfusion of materials containing certain particles.

Features:

1. The tail screw fine adjustment structure makes the pump have high metering accuracy and repeat consistency, and the accuracy is better than +0.5%.

⒉The metal part in contact with the material is made of 316L stainless steel, which has better corrosion resistance.

3. The pump body is connected in a quick-disassembly mode, which is convenient for disassembly, assembly and cleaning, and meets the cleaning requirements of food hygiene standards.

Industry application:

It can be used for matching and modification of the filling part of the packaging machine. It is very suitable for filling cream, honey, electrolyte, medicinal solution, biochemical reagent, chemical liquid, essential oil, essence, lotion, perfume, nail polish and other medium and high viscosity homogeneous liquid materials.