Zirconia Ceramic crucible for casting melting

Zirconia Crucibles for Consistent, High Temperature Melting

- Description

- Inquiry

Zirconia Ceramic crucible for casting melting

The description of zirconia ceramic parts

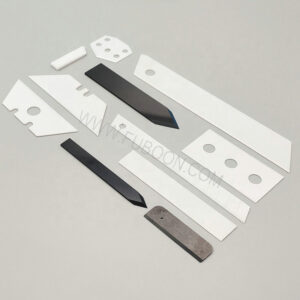

FUBOON Zirconia ceramic parts are made of zirconium oxide ceramics which is a kind of strongest technical ceramic material with exceptional strength, high toughness, and superb reliability. These outstanding characteristics result in excellent resistance to wear and corrosion.

Product Description

- High density

- Low thermal conductivity.

- Chemical inertness

- Resistance to molten metals

- Ionic electrical conduction

- Wear resistance

- High fracture toughness

- High hardness

Zirconia Ceramic crucible for casting melting

Zirconia ceramic are used in shaft , plunger, high-Pressure cleaning machines. sealing structure, auto mobile Industrial, oil drilling equipment, Insulation parts in electrical equipment , ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. | |||

Zirconia ceramics performance | Density | g/cm3 | ≥6.0 |

Water absorption | % | <0.05 | |

Firing temperature | °C | 1550 | |

Hardness | HV | 1350 | |

Bending strength | MPa | 950 | |

Compression strength | Mpa | 25000 | |

Breaking tenacity | Mpa·m1/2 | 8 | |

Hot expansion coefficient | /°C | 9.5×10-6 | |

casting ceramic crucible, ceramic boat crucible, ceramic boat crucible, smelting ceramic crucible

zirconia ceramic crucible, 5ml 10ml 15ml 20ml 25ml 30ml 50ml 100ml 150ml 200ml

We can supply 95%, 99.7% alumina ceramic crucible and zirocnia ceramic crucible according to customer’s drawings, samples and performance requirement.

1.High purity>99.7%

2.Max service temperature 1700.C

3.Good thermal shock

Zirconia (ZrO2) special crucible can withstand the high temperature up to 1700.C and has very good resistance to chemical erosions and thermal shock. Zirconia crucible is ideal for the melting of gold, glass, metal processing / molten glass, rapid thermal cycling, gemstone purification for jewelry industry etc.

Corundum – mullite – Zirconia Crucible size for reference :

| Crucible capacity(Liter) | Furnace crucible size(ID x OD x H) |

| 1L | Φ85x150x300 mm |

| 3L | Φ138x198x300 mm |

| 5L | Φ160x230x300 mm |

| 10L | Φ265x310x300 mm |

| 20L | Φ265x310x400 mm |

Crucible materials :

Zirconium oxide, Quartz, Alumina,Fused alumina zirconia and other materials.

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Main application :

Firing other high melting point material, which is mainly used for the melting temperature with Pt, Rh, Au and other precious metal.