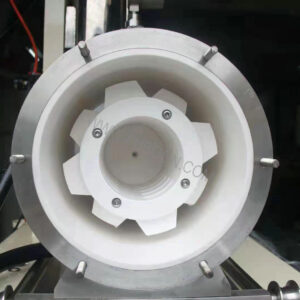

Zirconia ceramic plunger

- Description

- Inquiry

Zirconia ceramic plunger

Material Performance

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | Customized | |

| Density | g/cm3 | 6.0 |

| Zirconia Content | % | 94.4% |

| Gas permeability | 0 | |

| Water Absorption | 0 | |

| Crystal Size | um | 0.5 |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 78 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm²) | 11.5(1175) |

| Flexural Strength(20°C) | Mpa | 800 |

| Compressive Strength(20°C) | Mpa | 2000 |

| Modulus of Elasticity(20°C) | Gpa | >200 |

| Fracture Toughness(20°C) | MPam1/2 | 9.0 |

| Thermal Properties | ||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 2.5 |

| Thermal Expansion Coefficient | 10-6/°C | 9.6 |

| Thermal Shock Resistance | T°C | 250 |

Zirconia ceramic plunger

Product Feature: Advanced ceramic materials with high performance are used High hardness, wear resistance, high temperature resistance, corrosion resistance,No pollution to the use of media and other properties

Product application: Ceramic plungers are used in a variety of industries, including chemical processing, oil and gas, water treatment,

pharmaceuticals, and semiconductor manufacturing. They are commonly found in reciprocating pumps, high pressure pumps and hydraulic pumps.

pharmaceuticals, and semiconductor manufacturing. They are commonly found in reciprocating pumps, high pressure pumps and hydraulic pumps.

Product characteristics:

- Ceramic plungers are made of high-performance ceramic materials, which have the advantages of high hardness, high wear resistance, high temperature resistance, corrosion resistance and no pollution to materials.

- Among various metering pumps, ceramic pumps have the highest accuracy, which can reach ±3%, and maintain long-term stability and high repetition consistency.

- The micro-porous structure of ceramic plunger working face obtained by unique processing means has self-lubricating effect and no sealing ring is needed.

- The surface of cavity and plunger is machined into mirror by advanced high-precision internal and external grinder. The surface of cavity is made of fluid structure without dead angle and groove, which is convenient for cleaning and disinfection.

- The pump body structure is made of 316L stainless steel, which is connected with ceramics through a specific process.There are no other impurities and it is easy to disassemble.