Zirconia Pin Ceramic Rod for Electronics

- Description

- Inquiry

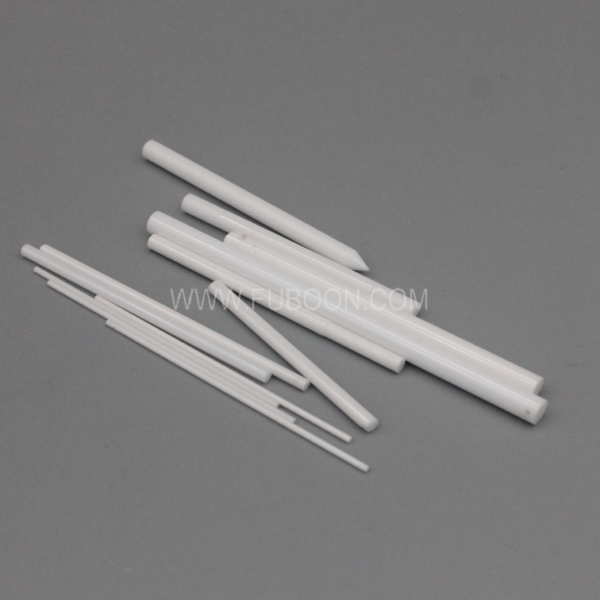

Zirconia Pin Ceramic Rod for Electronics

The description of zirconia ceramic parts

Zirconia ceramic parts are made of zirconium oxide ceramics which is a kind of strongest technical ceramic material with exceptional strength, high toughness, and superb reliability. These outstanding characteristics result in excellent resistance to wear and corrosion.

We have been offering a selection of partially stabilized zirconia, including Y-TZP( yttria-stabilized), MSZ ( magnesia stabilized ), CSZ- (ceria stabilized). Each stabilized zirconia provides unique and specific properties that meet the demands of extreme applications found in many industries.

With our production capability through CNC, precision grinding machines, we are able to provide many different level precision zirconia ceramic parts to meet customers’ high precision assembly needs.

The main features of zirconia ceramic parts

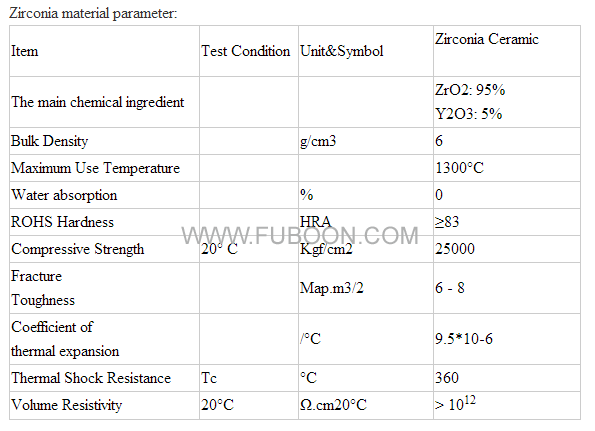

1.High density: over 6 g/cm3, which makes it the densest body of the ceramic products

2.High hardness: over 9 on Mohs scale, diamond being 10, with a satin-smooth surface finish

3.High toughness: over 1200 MPa, approx. 4 times in comparison with 95% alumina

4. Excellent wear resistance, it’s much better than aluminum oxide ceramics with a longer life cycle

5. Low thermal conductivity: less than 3 W/m.k at ambient temperature, so it’s an ideal thermal material

6. Good chemical and corrosion resistance, it’s equivalent to above 99% alumina

1.Product Composition: zirconia ceramic

2. Size: custom

3. Toelrance : ±0.001mm

4. Certification: ISO9001, SGS

Product Name | Small Thin 1mm 2mm Diameter ZrO2 Zirconia Pin Ceramic Rod for Electronics |

Material | yttria stabillized zirconia ceramic or magnisium zirconia |

Color | white or yellow |

Tolerance | ±0.001mm |

Grade | First Grade |

MOQ | 1 pcs |

Surface Finish | polished |

Composition | zirconia ceramic |

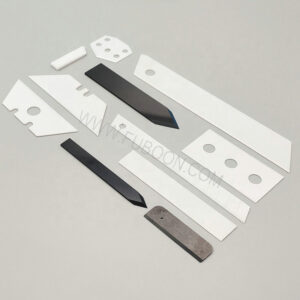

Zirconia ceramic is a material with high flexural roughness. Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performance is better than Tungsten carbide.

Features:

1.High mechanical strength and excellent wear resistance

2.Faster cutting rates and consistently good cutting quality, e.g. improved strength of spliced connections

3.Good surface finish and high fracture toughness

4.No corrosion, smooth running

5.Extended maintenance intervals

6.Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Applications:

1.Cutting food

2.Removing the burrs

3.Spinning machine

4.Slitting the stretch film on cast line

5.For paper core recutting machines

6.Fibers, tapes, film,leather,paper cutting machine application

Related Products

Ceramic valve ball and seat components

Ceramic valve components.Including valve ball(O-port and V-port),Seats and other parts for full-lined ceramic ball valve.

zirconia ceramic rectangular block for correct tool

Precision Zirconia Ceramic Plate

Zirconia ceramic rotor for bead mill

Zirconia ceramic rotors

Insulating zirconia ceramic rods for resistors

Insulating zirconia ceramic rods for resistors

zirconia ceramic bush

zirconia ceramic bush

Zirconia ceramic hair clipper blade

Ceramic blade for hairdressing

Zirconia ceramic Ferrules for Fiber Optic Patchcord/Jumper

Zirconia ceramic Ferrules for Fiber Optic Patchcord/Jumper

Zirconia Ceramic Plunger piston

Zirconia Ceramic Pump/Zirconia Ceramic Plunger/ceramic piston

Textile Industry Precision Technical Zirconia Ceramic Cutter Blades

Zirconia textile Ceramic blade

Zirconia ceramic assembling stainless steel components

Zirconia ceramic assemble with metal parts