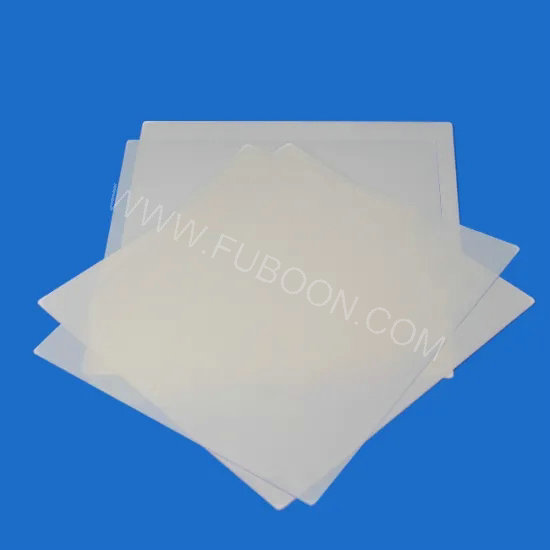

Substrato cerâmico de nitreto de alumínio de alta condutividade térmica

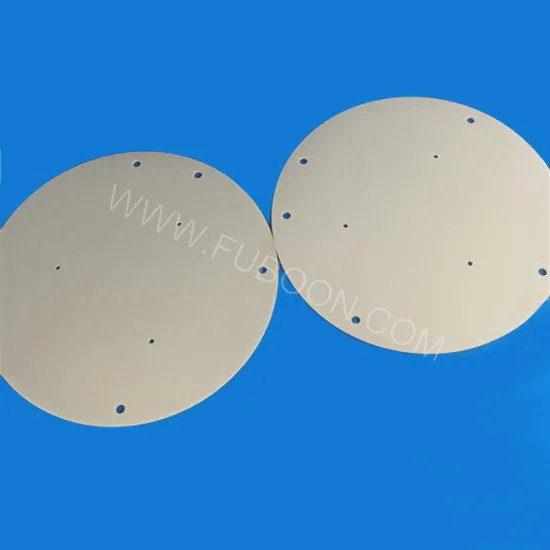

Wafer Cerâmico de Nitreto de Alumínio de Alta Condutividade Térmica

- Descrição

- Investigação

Substrato cerâmico de nitreto de alumínio de alta condutividade térmica

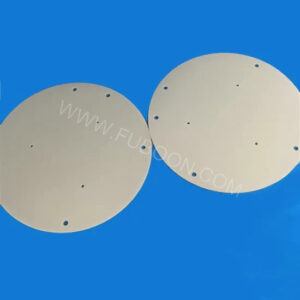

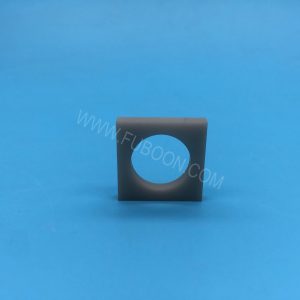

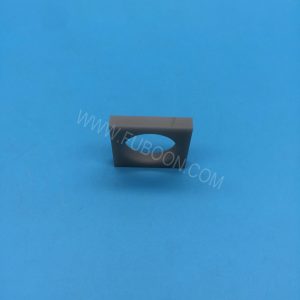

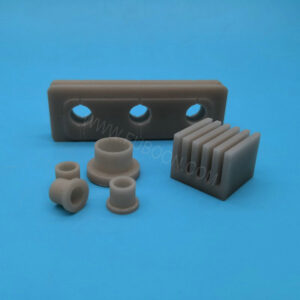

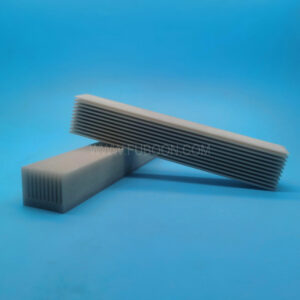

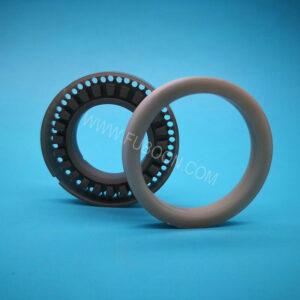

Disco de nitreto de alumínio cerâmico AlN condutor térmico Aluminum nitride ceramic wafer has a high thermal conductivity of more than 170W/m. k, high resistivity, baixa perda dielétrica, good insulation, and some other excellent properties. The ALN substrate is the best choice for a wide range of industrial insulating heat sink material of high power machinery and equipment such as high-frequency equipment substrate, high power transistor module substrate, high-density hybrid circuits, microwave power devices, power semiconductor devices, power electronic devices, optoelectronic components, laser-semi-conductor, LED, IC products, e assim por diante.

AlN substrate can be the best solution in electronics applications where strict conditions are required, such as power modules (MOSFET, IGBT), LED packages for cooling and protecting circuits, packages, and modules.

Substrato cerâmico de nitreto de alumínio de alta condutividade térmica

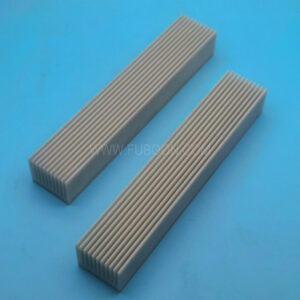

A especificação de bolachas de cerâmica e substrato

| Material | nitreto de alumínio (AlN), alumina(al2o3), zircônia(ZrO2), nitreto de silício(Si3N4), carboneto de silício(SiC) |

| dissipadores de calor para sistemas de iluminação | Cinza, preto, branco, pink, marfim, yellowish available |

| Capacidade dimensional | OD can be 400mm, Thickness can be range from 0.30mm to 30mm |

| Tolerância | OD can be ± 0.01mm, Thickness can be ± 0.005mm |

| Tratamento da superfície: | natural surface, lapidação, diamond-like polishing, metalização, glazed |

The main features of AlN ceramic wafers and substrate

1. Alta condutividade térmica (170 ~220) W / m.k, it’s 5~8.5 times higher than that of alumina

2. Similar coefficient of thermal expansion to that of silicon (E), it helps to achieve high reliability of Si chip

3. High insulation resistance and voltage resistance strength, but low dielectric constant and dielectric loss

4. Alta resistência mecânica, it’s up to 450MPa and very dense ceramic body free of porosity

5. It offers very high purity up to 99%, also it’s free of toxicity and meets RoHS, REACH regulation