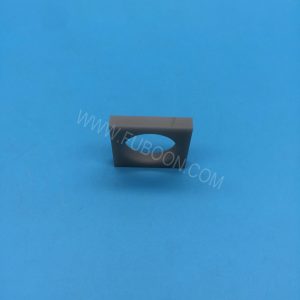

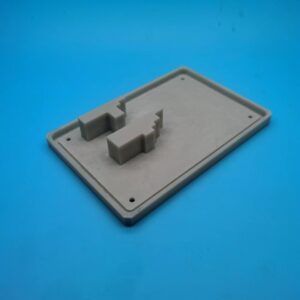

Placa de cobertura do aquecedor de nitreto de alumínio de prensagem a quente

- Descrição

- Investigação

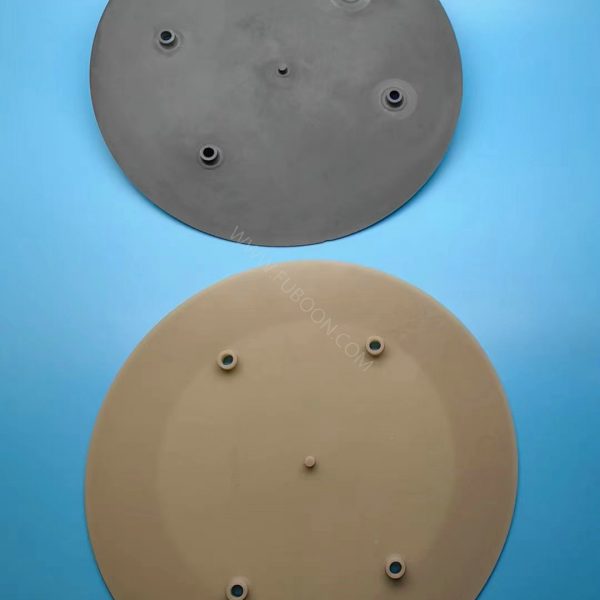

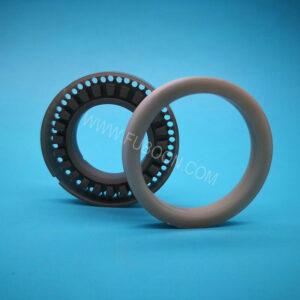

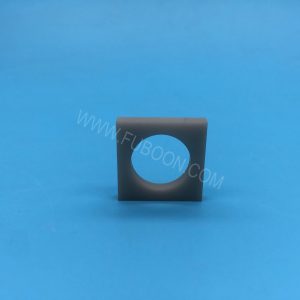

Placa de cobertura do aquecedor de nitreto de alumínio de prensagem a quente

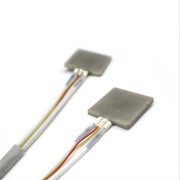

Hot-pressing Aluminum Nitride heater Cover Plate with thinnest thickness 0.75mm.

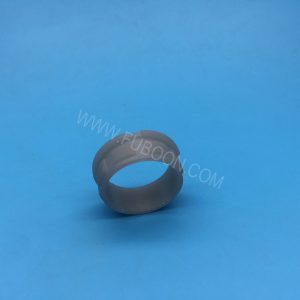

1.The material is very difficult to machine due to the high hardness and brittle, so it is very easily to have chips or scratches when handling or machining which lead to very high rejection rate.

2.Hot pressing aluminum nitride ceramics are sintered by vacuum hot pressing, the sintering process is more difficult than pressureless sintering. The aluminum nitride purity is up to 99.5%(without any sintering additives), and density after hot pressing reaches 3.3g/cm3, it also has excellent thermal conductivity and high electrical insulation. The thermal conductivity can be from 90 C/(BOMBA DE ENCHIMENTO CERÂMICO FUBOON·k) para 210 C/(BOMBA DE ENCHIMENTO CERÂMICO FUBOON·k).

3.The thinnest thickness only 0.75mm which is also difficult to machine.

The application of the Hot-pressing Aluminum Nitride heater Cover Plate:

-Cover plate heater for semiconductor

– Cover plates and MRI equipment(Magnetic Resonance Imaging)

-High-power detectors, plasma generators, military radios

-Electrostatic chucks and heating plates for semiconductors and integrated circuits

– Infrared and microwave window material

Material Features

1.″* 4″

2.″* 4″ (70-180 Wm-1K-1), ″* 4″

3.″* 4″

4.″* 4″

5.″* 4″

6.″* 4″

7.″* 4″, ″* 4″ (″* 4″

″* 4″; ″* 4″).

Typical Specification:

| Pureza: | >99% |

| Densidade: | >3.3 g / cm3 |

| Compress Strength: | >3,350MPa |

| Força de flexão: | 380MPa |

| Condutividade térmica: | >90C/(BOMBA DE ENCHIMENTO CERÂMICO FUBOON·k) |

| Coeficiente de expansão térmica: | 5.0 x 10-6/K |

| Máx.. Temp: | 1,800° C |

| Resistividade volumétrica: | 7×1012 Ω·cm |

| Rigidez dielétrica: | 15 kV/mm |